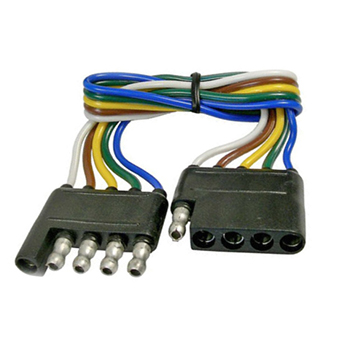

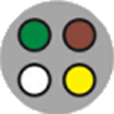

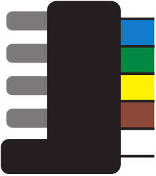

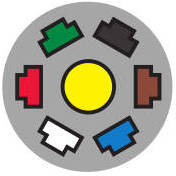

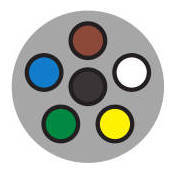

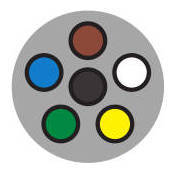

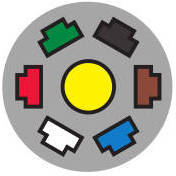

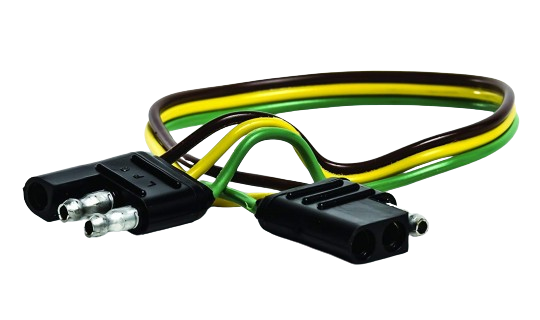

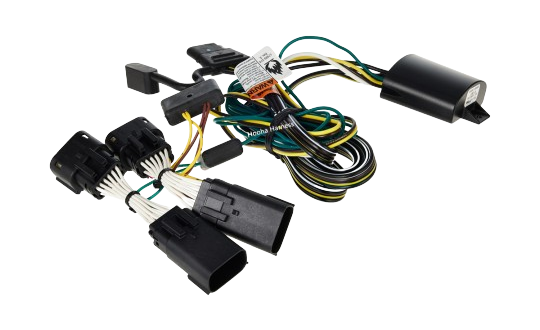

Trailer wire harness assembly

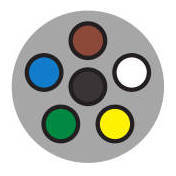

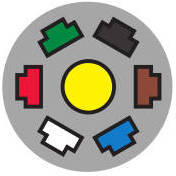

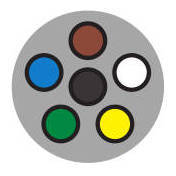

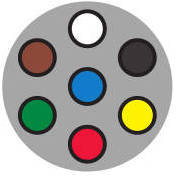

A Trailer Wire Harness Assembly is a specialized system of electrical wiring designed to connect and power various components of a trailer. It ensures reliable electrical connections between the trailer and the towing vehicle, facilitating the operation of essential features such as lighting, brakes, and turn signals.

Key Features:

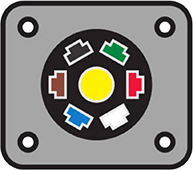

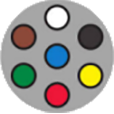

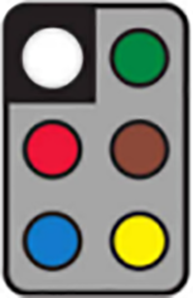

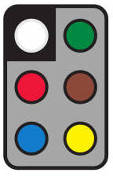

1.Comprehensive Connectivity: Integrates multiple wiring lines into a single, organized assembly, simplifying the connection between the trailer and towing vehicle.

2.Durable Construction: Built with high-quality materials to withstand harsh environmental conditions, including exposure to moisture, heat, and vibration.

3.Versatile Design: Available in various configurations to match different types of trailers and towing vehicles, ensuring compatibility and flexibility.

4.Enhanced Safety: Provides reliable connections for critical functions such as brake lights, turn signals, and tail lights, improving safety and compliance with road regulations.

5.Easy Installation: Designed for straightforward installation, often with plug-and-play connectors, reducing installation time and complexity.

6.Customizable Options: Can be tailored to specific requirements, including additional features like trailer brake controllers and auxiliary power supplies.

Applications:

1.Automotive Trailers: Connects electrical systems for lights, brakes, and signals, ensuring proper function and safety during towing.

2.Cargo Trailers: Facilitates the operation of interior lighting, electrical brakes, and other components.

3.Recreational Vehicles (RVs): Powers essential systems such as exterior lighting and brake lights, ensuring smooth operation during travel.

4.Utility Trailers: Connects electrical components for proper signaling and lighting, essential for safe towing.

A Trailer Wire Harness Assembly is essential for ensuring that all electrical systems in a trailer function correctly and reliably. Its robust design and versatile configurations make it a vital component for safe and efficient towing operations.

Advantages of Using Trailer Wire Harness Assembly

1. Enhanced Safety

Trailer wire harness assemblies ensure reliable connections for brake lights, turn signals, and tail lights, significantly improving safety during towing. This enhances visibility and communication with other drivers, reducing the risk of accidents.

2. Simplified Installation

Designed with user-friendly features, these harnesses often come with plug-and-play connectors, making installation straightforward and reducing the time and effort required. This allows for quick setup and minimizes downtime.

3. Durability and Longevity

Constructed from high-quality, weather-resistant materials, trailer wire harness assemblies are built to withstand harsh environmental conditions, such as moisture, heat, and vibration. This durability ensures a long lifespan and reduces maintenance costs.

4. Versatility and Compatibility

Available in various configurations, these harnesses can be used with different types of trailers and towing vehicles. This versatility ensures compatibility across a wide range of applications, from small utility trailers to large recreational vehicles.

5. Organized Wiring

By consolidating multiple wires into a single, organized assembly, trailer wire harnesses prevent tangling and simplify troubleshooting. This organized approach makes it easier to manage and maintain the wiring system.

6. Customizable Options

Trailer wire harness assemblies can be customized to meet specific requirements, such as incorporating additional features like trailer brake controllers and auxiliary power supplies. This customization allows for tailored solutions to suit particular needs.

7. Improved Functionality

A well-designed wire harness assembly ensures that all electrical components of the trailer function correctly. This includes powering interior lighting, electrical brakes, and other essential systems, enhancing the overall functionality of the trailer.

8. Compliance with Regulations

Using a trailer wire harness assembly helps ensure compliance with road safety regulations. Properly functioning lights and signals are crucial for legal towing, and these harnesses help maintain adherence to these standards.

9. Cost-Effective Solution

Investing in a trailer wire harness assembly can save money in the long run by reducing installation time, maintenance costs, and potential repairs due to faulty wiring. The durability and reliability of these assemblies provide a cost-effective solution for trailer wiring needs.

10. Enhanced Towing Experience

By ensuring all electrical systems are properly connected and functioning, trailer wire harness assemblies contribute to a smoother and more enjoyable towing experience. Reliable lighting and signaling improve driver confidence and overall road safety.